About Jikko Knives

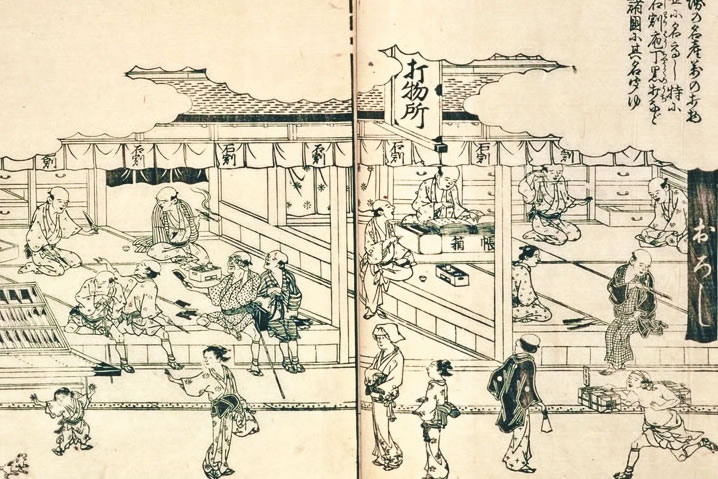

Jikko was established in 1901 in the Japanese city of Sakai located in the Osaka prefecture. Sakai is a well know as city where a number of Japan’s top quality knives are produced. We are one of the few manufacturers in the Sakai region who have such a long history and are considered as one of the top knife manufactures within the Sakai region.

In order for us to continue producing such high quality and well designed knives for the past 100 years, we constantly consult with a wide range of chefs throughout Japan, who provide us with first hand knowledge of what the look for and need in a high quality knife.

One thing that has separated our knives from the rest of the manufactures in the Sakai region and possibly all of Japan is our “Hatsuke” method. “Hatsuke” is a special finishing method used to give the blades an even finer angle, making our knives even sharper and at the same time allowing the blade to remain sharper for longer. Our “Hatsuke” method was developed after years of research and we believe that we have managed to find

the perfect blade angle to give our knives an even balance of sharpness and how long it remains sharp. If it is requested we can make the angle even finer making the knives even sharper, but it will affect how often you will need to sharpen the knife.

Founded in 1903,

A knife specialty store that has been around for over 120 years

JIKKO cutlery was founded in Sakai City (currently Sakai Ward, Sakai City) in 1891, and has a history of over 120 years as a Japanese knife manufacturer. Throughout this history, JIKKO has inherited the traditional craftsmanship technique passed down from its founder, JIKKO Jikou, while adapting to the changing times and continuing to provide the highest quality cutlery.

A knife specialty store founded in 1903

Founded in Sakai, Osaka, the town of cutlery. JIKKO Since Itaro was founded, we have been particular about the sharpness achieved by our craftsmen. Nowadays, customers love the quality of the sharpness of JIKKO cutlery, and more than 1 million knives have been shipped, and the knives are used by chefs at more than 100,000 restaurants.

the stores development

At the time of our founding, we only manufactured knives, but in order to pursue sharpness, we wanted to hear directly from our customers, so we opened the stores in Namba, Osaka in 2018. Since then, we have now opened stores in Sakai, Namba, Umeda in Osaka, Pontocho in Kyoto, and Kappabashi in Tokyo.

I was very happy that by opening a store, I was able to immediately reflect customer requests in my products. For example, what kind of sharpness do chefs want, what shapes are easy to cut, and what kind of appearance and design of knives they want, etc. We received many tips for product creation through many exchanges of opinions. . The products that were born from this exchange became the Shiko, Ginza, and Gion series of brand collections.

JIKKO kitchen knives

At JIKKO, in addition to the process of making knives, grinding, blades, and knives, we believe that knives are made by providing after-sales service so that customers will love knives for a long time.

What is Minako and how do you make kitchen knives by hand? I will explain some of them.

JIKKO kitchen knives

Grinding

Grinding is literally the process of sharpening and sharpening a kitchen knife.

The ground knives finished from blacksmithing are in the state of unsharpened boards. From here, we will scrape unnecessary parts and sharpen them carefully to create a sophisticated shape unique to kitchen knives.

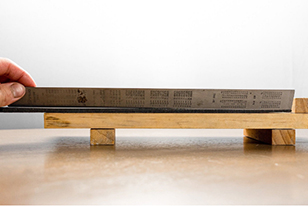

Hit the chisel

Hit the knife on the ground that came up from the blacksmith to straighten it.

The ground knife may look straight, but in the eyes of the craftsman, its surface is slightly distorted. (Fig. 5) This distortion is a great enemy for kitchen knives.

If the distortion becomes severe, the blade will not hit the grindstone perfectly. Of course, if you keep sharpening, you will be able to hit it someday, but the finished kitchen knife will become smaller and you will not be able to make the product you want.

How to create the smooth blade you want with the least amount of sharpening depends on the skill of the craftsman who drives the chisel.

-

Figure 5 Example of ground distortion -

A craftsman hitting a chisel

Working with a circular grind

A huge vertical and horizontal whetstone called a circular whetstone is used to carve out the delicate shape of a kitchen knife.

The process varies depending on the type of kitchen knife to be made and the steel material used, and the grindstone used also differs from time to time.

While always checking the overall balance and shape, we carefully and delicately, sometimes boldly, carve out the knives that the craftsmen imagined in their heads.

Working with a vertically rotating circular grind

Re-distortion

When you scrape metal, the kitchen knife is inevitably subjected to strong force and heat, and it is distorted again. The process of shaving, checking for distortion, removing any distortion, and shaving again is performed a total of eight times until the single-edged knife is completed.

Meaning to remove distortion

If you think about efficiency, you may think that you should remove the strain at the end of grinding instead of re-distorting it eight times.

However, if you do not correct the distortion each time, the distortion will accumulate, and eventually it will become a large distortion, which will affect the sharpness of the knife. Therefore, at JIKKO, every time we work, we see and remove distortion.

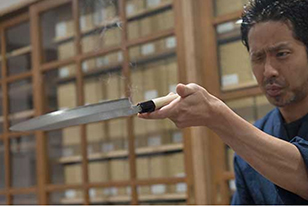

What is the sharpening of JIKKO's strengths?

One of the strengths of JIKKO cutlery is its sharpening technique. A knife is a tool that always loses its sharpness. Not only will the knife become sharper, but if you sharpen it yourself, the shape of the knife may become deformed and the knife may not be able to perform as intended.

A lifelong relationship after purchase

We believe that our relationship with our customers begins from the moment they purchase a knife. This is because knives are tools that always require aftercare. Through sharpening and repairs, we would like to continue to support you so that you can continue to use your knives for many years to come.

JIKKO 's sharpening repair service not only sharpens the cutting edge, but also inspects and repairs the structure of the knife. This is a knife repair technique that is difficult for a professional who only specializes in sharpening, and is only possible by a knife manufacturer.

Our knife craftsmen take responsibility for maintaining the knives to make them easier to use and sharpen by hand.

About us

| Company name |

Ltd JIKKO

|

|---|---|

| Founded | January 1901 |

| Capital | 10 million yen |

| Representative |

Professional experience: 25 years or more after graduating from university |

| number of employees | 73 people |

| Business content | Manufacture and sale of cooking knives and cutting tools |

| location | 590-0931 1-1-9 Nishikinochonishi, Sakai-ku, Sakai-shi, Osaka |

| TEL | 072-229-2244 (main) |

| FAX | 072-229-2271 |

| URL | https://jikkocutlery.com/ |

| Affiliation | |

| Eligible invoice issuing business registration number | T5120101003513 |

| List of stores | |

| Awards |

|